*This post may contain affiliate links. As an Amazon Associate we earn from qualifying purchases.

Scuba tank markings: they may seem cryptic at first glance, filled with an array of symbols, numbers, and initials. Yet, each marking serves a crucial purpose, encoding vital information about the tank’s manufacturing details, testing dates, and safety measures. These markings act as the silent communicators of the underwater world, ensuring that divers have the necessary data to dive safely.

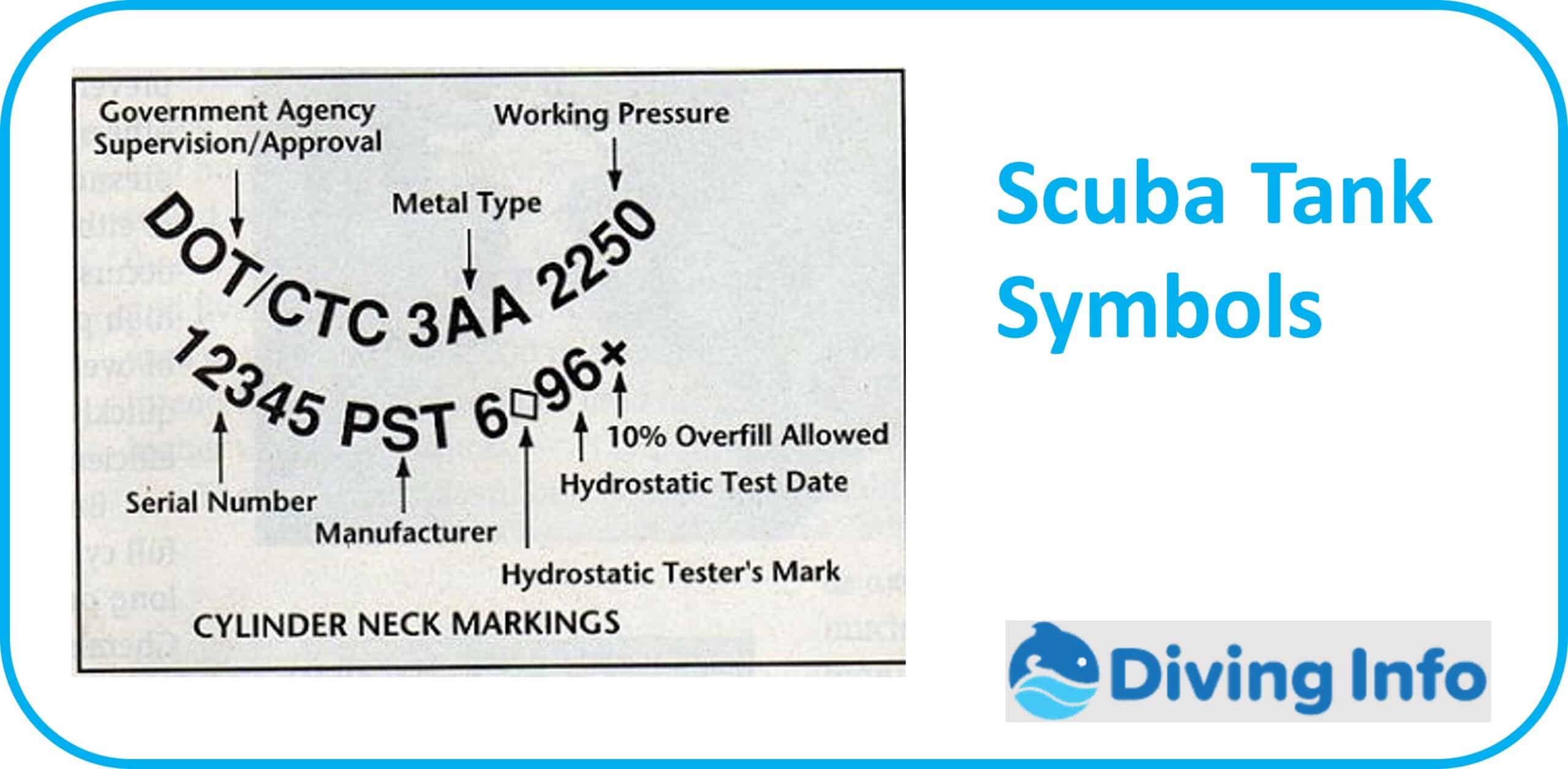

Scuba tank markings provide crucial information about a tank’s manufacture, material, and safety tests. They indicate government approvals, the metal used, and the tank’s working pressure, aiding in safe diving practices.

In this article, we will delve into the enigmatic world of these markings, offering you a comprehensive guide to unlock their secrets. We will guide you on how to read scuba tank markings and navigate through the different types of markings that can tell us about the government’s approval, the metal a tank is made of, and the working pressure it can handle. Finally, we will address some commonly asked questions, leaving you with a well-rounded understanding of the topic.

So strap on your gear, and let’s dive in to unravel the mysteries of scuba tank markings.

Key Takeaways

| Every marking and sticker on a scuba tank is there for a reason, providing crucial information about the tank’s manufacture, safety, and intended use. |

| Understanding tank markings is key to ensuring your safety as a diver and can also help you choose the right tank for your specific diving needs. |

| Regular inspection and testing of scuba tanks is vital. Hydrostatic testing should be carried out every five years, while an annual visual inspection is recommended. |

| Aluminum and steel are the most common materials used to make scuba tanks, each with its own pros and cons. Knowing the differences can help you make an informed decision. |

| The world of scuba diving is vast and intriguing, and knowledge is your greatest tool. Keep learning, keep asking questions, and never stop exploring. |

Decoding Scuba Tank Symbols: A Guide to Reading Markings

Are you ready to dive into the language of scuba tanks? Understanding scuba tank markings can seem intimidating, but it’s crucial for maintaining your equipment and ensuring your safety while diving. This guide will walk you through the steps to decode these symbols.

Firstly, it’s essential to know that these markings contain several types of information. The primary elements you will encounter are:

- Manufacturer details

- Serial number

- Manufacturing date

- Material composition

- Tank capacity

- Test dates

- Working pressure

All this information can be accessed directly from your scuba tank, giving you the power to become an informed diver.

This table provides a clear, concise guide to the most common scuba tank markings and their meanings.

| Marking | Meaning |

| DOT | Department of Transportation – certifies compliance with USA safety standards |

| CTC | Canadian Transport Commission – certifies compliance with Canadian safety standards |

| BS | British Standard – certifies compliance with UK safety standards |

| AL | Aluminum – indicates the tank is made of aluminum |

| ST | Steel – indicates the tank is made of steel |

| 6351 | An aluminum alloy – specifies the type of aluminum used |

| 3000 PSI | Working Pressure – shows the maximum pressure of gas the tank can safely hold |

| 3AL | DOT specification – shows the tank has been made in compliance with a specific DOT specification |

This video explains the markings on Scuba tanks.

Here’s a simplified way to read these markings:

- Manufacturer details: These are usually the first characters on the tank and indicate the company that manufactured the tank. For instance, ‘LUX’ stands for Luxfer, a popular tank manufacturer.

- Serial number: Following the manufacturer details, this unique number helps in tracking the tank’s history and servicing records.

- Manufacturing date: This is usually represented in a month/year format. For example, 05/23 would denote May 2023.

- Material composition: The symbols ‘AL’ or ‘ST’ can be seen representing Aluminum or Steel tanks respectively.

- Tank capacity: This denotes the volume of air the tank can hold, typically measured in cubic feet or liters.

- Test dates: Tanks undergo hydrostatic and visual testing. The dates of these tests are usually stamped or written on the tank.

- Working pressure: This is the pressure that your tank has been designed to hold, generally indicated in PSI or BAR.

Remember, each scuba tank may have slightly different markings based on its manufacturer and country of origin. Therefore, it’s crucial to familiarize yourself with these variations. Notably, scuba tank markings play an invaluable role in diving safety.

By understanding and monitoring these markings, you can ensure that your equipment is up-to-date and maintained according to the highest standards.

Understanding Scuba Tank Inscriptions: Interpreting Symbols for Safe Diving

Taking a step further in our dive into scuba tank markings, let’s focus on some specific symbols you might encounter and understand their significance.

Recognizing Regulatory Compliance with Scuba Tank Markings

Government certifications on scuba tanks are a nod to their safety and standard compliance. They vary from country to country, but common ones include:

- DOT (Department of Transportation) for the USA.

- CTC (Canadian Transport Commission) for Canada.

- BS (British Standard) for the UK.

These symbols assure that the tank complies with each country’s safety and quality regulations. Always ensure your tank carries these certifications; your safety may depend on it!

Unveiling Material Composition through Scuba Tank Markings

Different materials make different tanks. Aluminum (AL) and steel (ST) are common ones. Aluminum tanks are lightweight and resistant to corrosion, but they’re also more buoyant than steel tanks, which are heavier but offer better durability and capacity. Recognizing the tank’s material will help you choose the best one for your diving style.

Decrypting the Makeup of Scuba Tanks through Their Symbols

Beyond just aluminum and steel, scuba tanks often contain information about the specific alloy used in their construction. For instance, tanks marked ‘6351’ indicate an aluminum alloy that was popular in the past but is less common today due to some safety concerns. Be sure to know your tank’s alloy to ensure it’s safe and suitable for your dive.

Interpreting Working Pressure Indications in Scuba Tank Markings

Working pressure is a crucial factor in scuba tanks. It tells you the maximum pressure of gas the tank can safely hold, usually denoted in PSI (pounds per square inch) or BAR. Common ratings include 2400 PSI or 3000 PSI. Knowing the working pressure is crucial for safe and efficient dives.

Unraveling Additional Scuba Tank Symbols

There might be more! Other markings can indicate special treatments the tank has undergone or extra certifications. For instance, ‘3AL’ indicates the tank has been made in compliance with a specific DOT specification.

Understanding these markings is like learning a new language – the language of safety and preparation in the world of scuba diving.

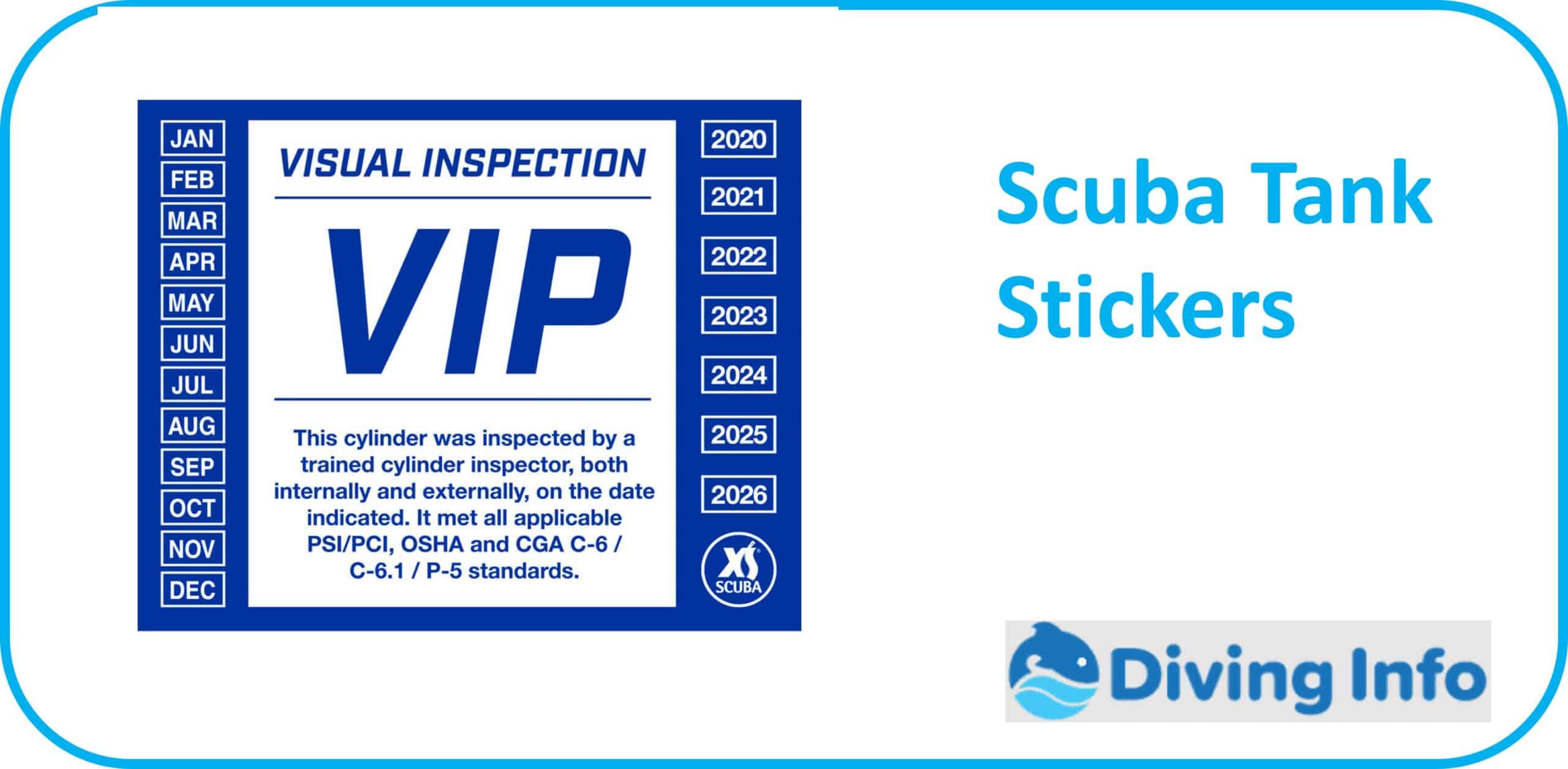

Exploring the World of Tank Stickers: Their Meaning and Significance

Alongside the stamped markings, your scuba tank will often sport some stickers, each one providing vital information about the tank’s safety and suitability for certain types of diving.

Understanding Hydrostatic Testing Stamps: The Lifeline of Your Scuba Tank

Your scuba tank needs to prove its strength and safety regularly. This proof comes in the form of hydrostatic testing stamps. These stickers are placed on the tank after it passes a hydrostatic test, a process where the tank is filled with water and pressurized to test its strength and elasticity.

Typically, tanks need to be tested every five years, but local regulations may vary. The stamp will usually show the date of the last test and the initials of the testing facility. Make sure to check for this sticker before planning your dive!

Deciphering Visual Inspection Tags: A Seal of Maintenance

Scuba tanks should also undergo an annual visual inspection. This is to check for any internal corrosion, cracks, or other damages that might compromise the tank’s safety.

After passing this inspection, a sticker is affixed to the tank, often around the neck, showing the date of the inspection and the inspector’s signature. These tags are crucial to ensuring your tank is safe and well-maintained.

Unmasking the Symbols on Nitrox SCUBA Tanks: A Special Case

Nitrox tanks contain a higher percentage of oxygen compared to regular air tanks. This composition requires special handling, and as such, Nitrox tanks carry specific stickers indicating their contents.

Typically, these tanks will have a green and yellow sticker stating ‘Enriched Air Nitrox’ along with the maximum operating depth. Diving with Nitrox has its advantages, but it’s crucial to be certified and understand the considerations involved.

Dive stickers may be small, but they pack a punch of information.

FAQs

What’s the Typical Size of a Scuba Tank?

The standard size of a scuba tank can vary, but the most common ones used in recreational diving are the AL80 and the Steel 80. These tanks hold about 80 cubic feet of gas at 3000 PSI. The AL80 is made of aluminum, while the Steel 80 is made of steel.

Do Scuba Tanks Have an Expiry Date?

Scuba tanks do not have an “expiry date” per se. However, they do require regular testing and inspection to ensure they are safe for use. Hydrostatic testing should be done every five years, while a visual inspection is recommended annually. Tanks that fail these inspections are deemed unsafe and should be retired.

Which Two Metals are Commonly Used in Scuba Tanks?

Aluminum and steel are the two most commonly used metals in scuba tanks. Aluminum tanks are lightweight and resistant to internal corrosion, making them suitable for recreational divers. Steel tanks, on the other hand, are heavier but have a higher capacity and are more durable, preferred by technical divers.

Conclusion

From the etched symbols to the color-coded stickers, every marking on a scuba tank has a purpose, telling a story about its origin, safety, and suitability for your dive. These markings contain essential information about the manufacturer, the tank’s composition, its testing history, and its certified use.

Recognizing and understanding these markings equips you as a diver to make informed decisions for a safer and more enjoyable diving experience. Decoding these symbols is like learning a new language – the language of safe diving. Armed with this knowledge, you’re ready to dive deeper into the world of scuba diving, fully prepared and informed. Happy diving!